Every builder has a story about a small miss that turned into a big change order. The fix is not magic. It is a tight preconstruction checklist that catches conflicts before they hit the slab. Industry groups have preached this for years for a reason. The International Code Council’s Residential Code spells out many of the field checks reviewers expect to see in drawings. NKBA publishes practical clearances that make kitchens work in real life. ENERGY STAR and EPA WaterSense give measurable specs that reduce callbacks. When you pull these threads into one preconstruction pass, you protect budget and schedule.

Preconstruction checklist that pays for itself

Start with the tape measure checks. Confirm stair geometry against the International Residential Code so rise, run, headroom, and handrails pass on day one. Verify bedroom egress window sizes and sill heights on the plans to avoid costly reorders. Make sure garage separation and the door to the house match your local adoption so no one is scrambling for the right door slab after framing. The U.S. Census Bureau’s Survey of Construction shows single family homes already spend months in the field, which means every week saved before ground break compounds through the schedule.

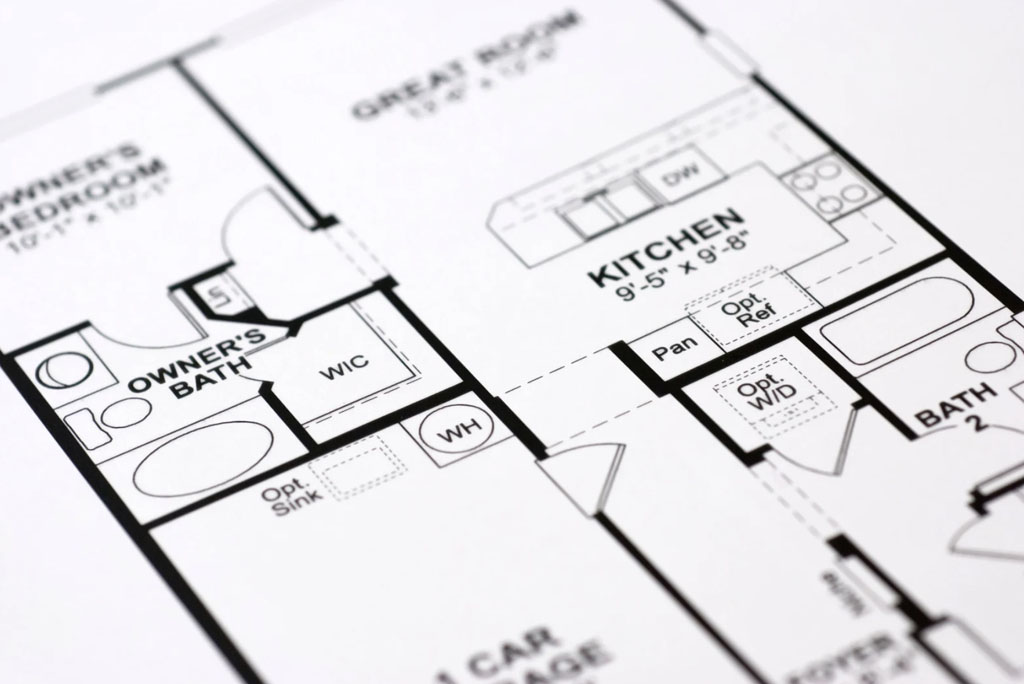

Move to layout and flow. NKBA’s planning guidance is the easiest way to avoid kitchen friction. Draw 42 inch aisles for one cook, 48 inches where two people will work, landings around the range, sink, and fridge, and island seating that actually fits. In baths, confirm 30 inches clear in front of toilets and 24 inches on at least one side so the room does not feel pinched. These are small line moves that prevent expensive cabinet or plumbing relocations once rough in begins.

MEP and structure coordination that kills surprises

Most change orders live where ducts, pipes, and beams collide. Do a coordinated pass before you order trusses. Mark the main duct runs, bath fan routes, dryer vent, and hood vent termination on the plans. Confirm the path clears beams, joists, and bracing. ENERGY STAR emphasizes sealed, short duct paths for comfort and efficiency, and those routes only happen when they are reserved up front. Note electrical panel size and location, call for AFCI and GFCI where required, and leave wall space for real world clearances at water heaters and furnaces per manufacturer instructions.

Plumbing deserves the same treatment. Stack wet walls wherever possible. Verify that shower valves, niches, and drains align with framing before tile is ordered. EPA WaterSense labeled fixtures can cut water use without buyer pushback, but only if rough heights and valve types match the spec. On structure, double check point loads down to footings, portal frame details at garage openings, and braced wall panel lengths and methods. Clear bracing that matches the book is one of the fastest paths to clean inspections and fewer field fixes.

Permit ready details that speed approvals

A checklist should also make the permit reviewer’s job easier. Page one should list adopted code editions, design criteria for snow, wind, seismic, live loads, and the chosen energy path so there is no guesswork. If you are using a performance path for energy, make sure the compliance report matches the window and door schedule. The Department of Energy’s REScheck tool is practical for many jurisdictions, and clean submittals that align with the plans come off review faster. Clear site plans with setbacks, finished floor elevations, drainage arrows, and downspout locations prevent late redlines on small lots where stormwater is sensitive.

Specs and orders locked before concrete

Checklists close the loop by locking the things that trigger rework if they move later. Confirm appliance models and openings, right size the hood and add a dedicated circuit for a microwave drawer if planned, and verify venting method so you do not discover a recirculating unit on a gas range. Confirm cabinet runs, finished end panels, and crown decisions so framing does not box you in. Verify door swings and clearances at laundry and pantry. In small plans, a half inch hinge issue can force a costly reframe. This may feel like extra work in the office, but the Project Management Institute has long tied clear scope definition to lower rework and better outcomes, and housing is no exception.

How W. L. Martin plans make checklists easy

W. L. Martin Home Designs builds many of these checks into the drawings so your preconstruction meeting becomes faster and more reliable. Plans call out egress window sizes and stair geometry on the sheets, list code editions and design criteria on the cover, and include braced wall or shear plans with methods, lengths, and hold downs shown instead of implied. Kitchen and bath layouts are drawn with NKBA friendly clearances, and appliance openings are dimensioned so purchasing can order with confidence. Mechanical and electrical notes reserve real wall space for panels and equipment, and site plan templates make setbacks and drainage obvious.

If your jurisdiction wants sealed calculations, portal frames at a specific garage opening, or a different frost depth, the sets can be paired with local engineering or addenda so your permit review is as smooth as your precon. That kind of clarity is exactly how a smart plan choice saved one of our builders significant money in the story we shared in How a Plan Choice Put $20,000 Back in a Builder’s Pocket. The math is simple. Fewer surprises, fewer change orders, fewer days eaten by rework.

The bottom line for developers and plan buyers

Change orders will never be zero, but a good checklist will cut the volume and the cost. Use code aligned tape checks, NKBA clearances, ENERGY STAR and WaterSense specs, and coordinated MEP paths to remove the obvious traps. Pair that process with plan sets that are already reviewer friendly and you start faster and finish cleaner. W. L. Martin’s 400 to 3,500+ square foot plans are designed to make this work feel routine, which means more predictable budgets for developers and fewer headaches for homeowners building their next place. If you want a short preconstruction checklist you can run on every plan, we can share the one our builders use and point you to plan families where these details are already standard.

Leave a Reply