Practical swaps that protect buyer appeal and your margins

Value engineering is not about cheapening a house. It is about building the same perceived value with fewer parts, fewer steps, and fewer headaches. For small to mid-size homes, the win is huge because every corner, span, and SKU matters.

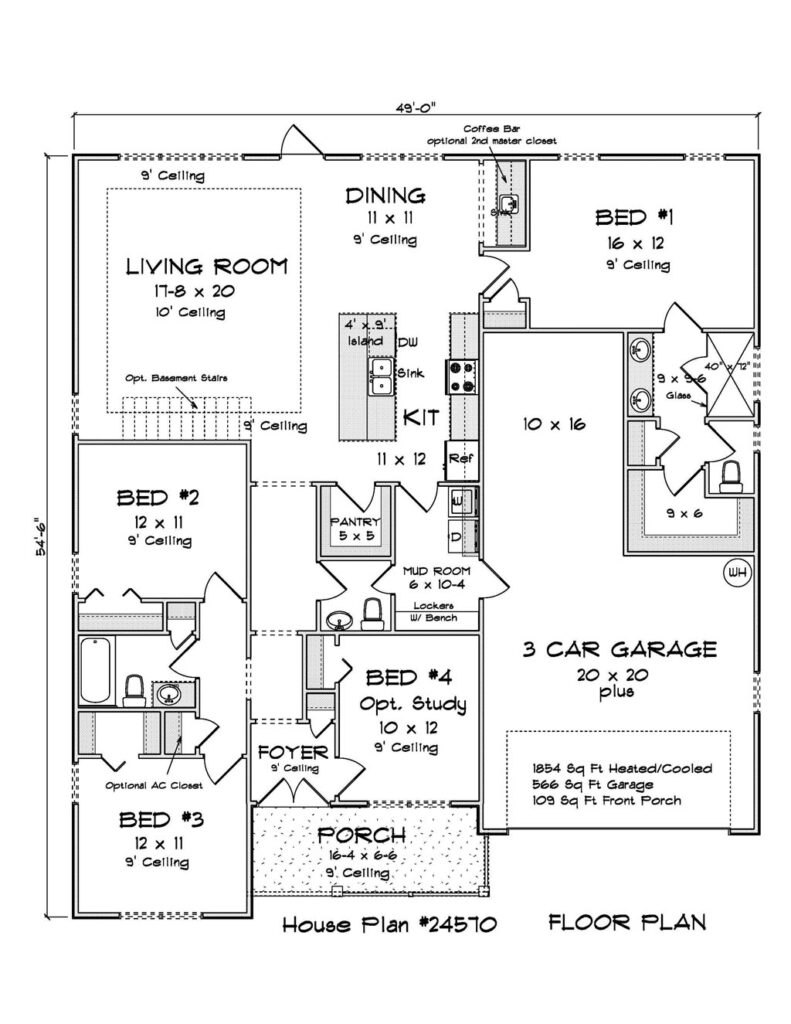

W. L. Martin Home Designs bakes value engineering into the plans from day one. Our footprints are efficient, our spans are truss friendly, plumbing cores are stacked, and window and door sizes are standardized so you spend less time solving problems in the field. Below is a simple, developer friendly playbook you can use on any 1,000 to 2,000 sq ft build, with a free swap list you can put to work on your next takeoff.

The short list of what really drives cost

- Corners and roof complexity

- Spans and load paths

- Kitchens and baths count and layout

- MEP travel distance and access

- Custom SKU creep in finishes

W. L. Martin plans tackle these where it counts. Most plans keep footprints to 4 to 6 corners, align bearing walls floor to floor, centralize wet rooms, and use simple gables or hips so truss packages drop in cleanly. That is value engineering built in.

Trade by trade plays that work

Site and foundation

• Choose simple rectangles and L shapes. Fewer corners means shorter footings and less formwork

• Where allowed, consider frost protected shallow foundations for slab on grade in cold climates to reduce excavation and concrete volume

• Standardize garage depths and porch sizes to match common rebar and form lengths

Framing

• Use advanced framing where your engineer and code official approve. 2×6 at 24 inches on center, single top plates with aligned loads, and insulated headers in non bearing walls reduce stick count and thermal bridging

• Keep roof geometry simple. Straight gables and clean hips make trusses faster to set and cheaper to buy

• Right size spans. A small shift in stair or bearing wall location can eliminate a steel beam or an LVL

• Repeat modules. 12, 24, and 36 inch dimensions keep sheathing and drywall cuts to a minimum

How W. L. Martin Home Designs helps

• Aligned loads between floors, truss friendly rooflines, repeated dimension modules, and details that support advanced framing where acceptable

Mechanical, electrical, plumbing

• Stack kitchens, baths, and laundry. Back to back wet walls shorten runs and reduce fittings

• Centralize the mechanical room. Shorter duct and line set runs improve comfort and lower install time

• Keep ducts inside conditioned space when possible. Fur-downs, dropped hallway ceilings, or truss chases can do it

• Prewire smart but simple. Conduit to future solar and EV saves a costly retrofit without overspec

How W. L. Martin Home Designs helps

• Most plans cluster wet rooms and show clear chases and drops so trades do not improvise on site

Envelope and windows

• Limit unique window sizes. Reuse 2 or 3 sizes for the entire house

• Use advanced framing corner and T wall details to add insulation where studs usually stack up

• Select siding systems that install fast. Prefinished fiber cement or engineered wood with simple trim profiles keeps labor predictable

How W. L. Martin Home Designs helps

• Window schedules use standard sizes and repeated units. Corner counts are restrained to keep linear feet of exterior wall and trim down

Kitchens and baths

• Design with cabinet modules in 3 inch increments. Fewer fillers, less custom work, faster install

• In secondary baths, use high quality one piece or multi piece surrounds. Save tile for the primary shower where buyers notice it

• Prefer large format tile and stacked patterns over intricate layouts to control labor

How W. L. Martin Home Designs helps

• Kitchen and bath layouts are planned on modular grids with appliance and vanity sizes that are easy to source in any market

Finishes that feel rich without high labor

• Luxury vinyl plank throughout common areas for speed, durability, and moisture tolerance

• Quartz with standard slab thickness and common colors. Reserve waterfalls for price points that demand them

• Three tier finish packages so you control substitutions instead of chasing one offs

How W. L. Martin Home Designs helps

• We can pair any plan with Bronze, Silver, Gold finish menus that align to your budget and supply chain

Your free value engineering swap list

Use this as a checklist against your current spec. The goal is to keep perceived quality the same while reducing parts and labor steps.

Framing

• 2×6 24 inch OC advanced framing where engineered and code approved

• Insulated headers in non bearing walls instead of solid lumber

• Trussed roofs over stick framed hips and valleys wherever the look allows

• Drop a corner when moving a wall will not hurt furniture layouts

MEP

• Back to back bathrooms on a shared wet wall

• Laundry stacked near kitchen core to shorten plumbing runs

• Ducts in conditioned space using truss chases or hallway drops

• 200 amp panel with a 1 inch conduit to garage for future EV. No expensive EVSE day one

Envelope and openings

• Repeatable window sizes. One tall, one wide, one slider used throughout

• Prefinished siding and trim packages with matched accessories

• Raised heel trusses to hit attic insulation R values cleanly at the eaves

Interior finishes

• LVP in common areas, carpet in bedrooms, tile only in primary shower

• Stock cabinet door style in three finishes, full overlay look without custom shop time

• 3 cm quartz in kitchen, 2 cm in baths if your market allows a mix

Exterior details

• Front porch sized for curb appeal but framed to standard lumber lengths

• Simple gable or hip facing the street. Keep valleys to a minimum

Why this works and where the data points

These moves line up with published guidance from industry groups that study first cost and long term performance. Advanced framing strategies reduce redundant studs and improve insulation continuity, which cuts material and can improve energy performance. Ducts inside conditioned space reduce distribution losses and callbacks related to comfort. Standardizing SKUs lowers procurement risk and speeds install. Truss friendly roof and floor systems reduce labor hours and crane time compared to complex stick framing.

W. L. Martin Home Designs plans lean into those same levers. Most of our 1,000 to 2,000 sq ft designs have 4 to 6 corners, stacked wet rooms, clear load paths, and simple roof forms so you buy fewer parts and spend less time coordinating trades. That is money you can keep or use to upgrade where buyers actually feel it, like primary showers, kitchen counters, and natural light.

Quick feasibility checklist you can run in 30 minutes

• Count corners. Target 4 to 6

• Check span map. Can trusses solve everything without steel

• Trace your wet wall path. Kitchen to baths to laundry in one line

• List unique window sizes. Keep it to three

• Confirm duct path inside the envelope

• Compare spec to a three tier finish menu

If you need a plan that hits those marks, filter W. L. Martin Home Designs by number of bedrooms, width, and garage inclusion, then match the spec to your market. We can also tune a plan for your lot and code requirements without breaking the VE backbone.

Leave a Reply